SEISMIC BRACING APPLICATIONS

Proper seismic bracing is critical to protect non-structural services and assets are protected and remain functional in the event of an earthquake. 80 per cent of the world’s earthquakes happen around the edge of the Pacific Plate, directly affecting New Zealand, Japan and the West Coast of both North and South America. In recent times we have witnessed 2011’s devastating magnitude 6.3 earthquake in Christchurch from which the city is still recovering, the magnitude 9.0 earthquake off the coast of Japan, causing a tsunami that killed around 25,000 people and led to the largest nuclear disaster in history, as well as countless smaller seismic events.

Australia sits on the Indo-Australian plate which is being pushed towards the north-east, colliding with the Philippine and Pacific plates and leading to a severe build-up of stress. It is this stress that causes the earthquakes we feel all over the country. According to research by geoscience Australia, there has been about one earthquake measuring 2.0 or greater every day in Australia for the past decade. Western Australia experiences the majority of these events but Adelaide is the most ‘at risk’ capital and has suffered more medium sized quakes in the past 50 years than any other.

With these facts in mind it is crucial to ensure that buildings and assets are properly protected and will continue to operate after a seismic event. Suspended non-structural building components are critical for the proper functioning of a building, and make up a high percentage of a building’s damage in a seismic event. Properly-engineered bracing and isolation of these services is particularly critical for essential facilities that must remain operational in the aftermath of an earthquake or seismic event (such as hospitals, fire/rescue, water/power, etc.), or facilities representing a substantial hazard to human life (such as schools, jails, etc.).

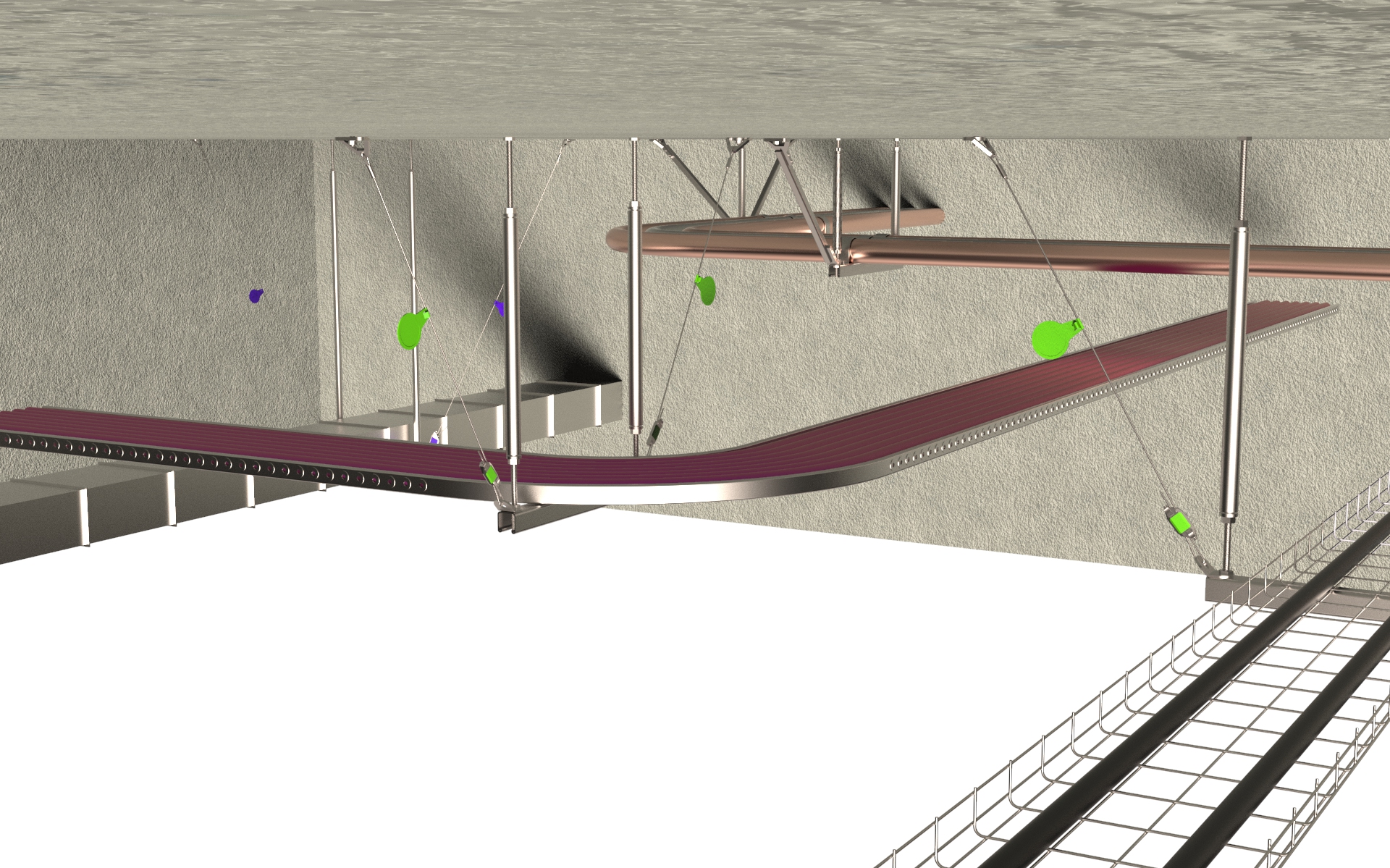

Gripple Seismic Bracing Systems are specifically designed and engineered to brace and secure suspended non-structural equipment (VAV boxes, fans, unit heaters, small in-line pumps, etc.) and components (HVAC duct, conduit/cable tray, and piping) within a building or structure to minimize damage from an earthquake or seismic event. Gripple ensures that the bracing meets the seismic design requirements of the non-structural components, in compliance with all relevant standards and specifications.

The types of MEP systems for which Gripple products can provide bracing & isolation solutions includes:

- Mechanical & HVAC

- Electrical & Cabling

- Piping/Plumbing

- Fire Protection

- Safety

- Emergency Power

- Security/Communications

Approvals & Certifications

- Gripple holds the following industry approvals for our Wire Bracing Systems:

- AS1170.4 and NZS4219 compliant

- In accordance with ANSI/ASHRAE 171

- OSHPD OPA 2123-10

- UL NEBS GR 63 Core Certification

- SMACNA Verification

- International Building Code (IBC)

- California State Building Code

- National Fire Protection Association (NFPA)

- American Society of Civil Engineers (ASCE) 7-05 Chapter 13

- Unified Facilities Criteria (UFC) 300 and 400

- American Society of Heating, Refrigeration, and Air Conditioning Engineers (ASHRAE)

- Federal Emergency Management Agency (FEMA)

- Engineered seismic bracing calculations and details based upon drawings/plans provided.

- PE stamped layout drawings for each service noting the proper location of Gripple Seismic Cable Bracing and/or Vibration Management products (spring mounts, vibration isolation pads, hangers, and accessories), per the scope of the project.

Seismic Projects

Gripple products has been utilised on an extensive number of high-profile job sites that include research labs, healthcare facilities, manufacturing plants, government & military sites, educational institutions, corporate offices, data centres and hotel/casinos including projects across Australia and New Zealand, for both new and retrofit installations.

Types of equipment and services that have been braced include: VAV boxes, sprinkler pipe, electrical cable tray, junction boxes, lighting, ductwork, plumbing, fan coil units, and more.

Below is a sample of projects where Gripple seismic bracing systems have been installed. For more information or details regarding completed projects, please contact the Polyplas International Area Manager in your region.

| Wheatstone LNG | Exxon Mobil PNG |

| Curtis Island LNG | Inpex LNG |

| Royal Adelaide Hospital | Sunshine Coast University Hospital |

| Royal Children’s Hospital – Perth | Bendigo Hospital |

| Frankston Hospital | Telstra Data Center |

| Wagga Wagga Hospital | ANSTO Nuclear Research Facility |

| Dunedin Stadium | Knox Plaza |

| Countdown Hornby, Ferrymead and Brackenfield | Pak ‘n save Wainoni |

| Wellington Tunnel | C4 Customs House Wellington |

| Christchurch Airport | Aldi Stores |

| Rockampton Hospital ICU | Townsville Hospital |

| Springfield mater Hospital | Coomera Sports Hall & Leisure Centre |

| PA Hospital Brisbane |