Seismic

Wire Bracing

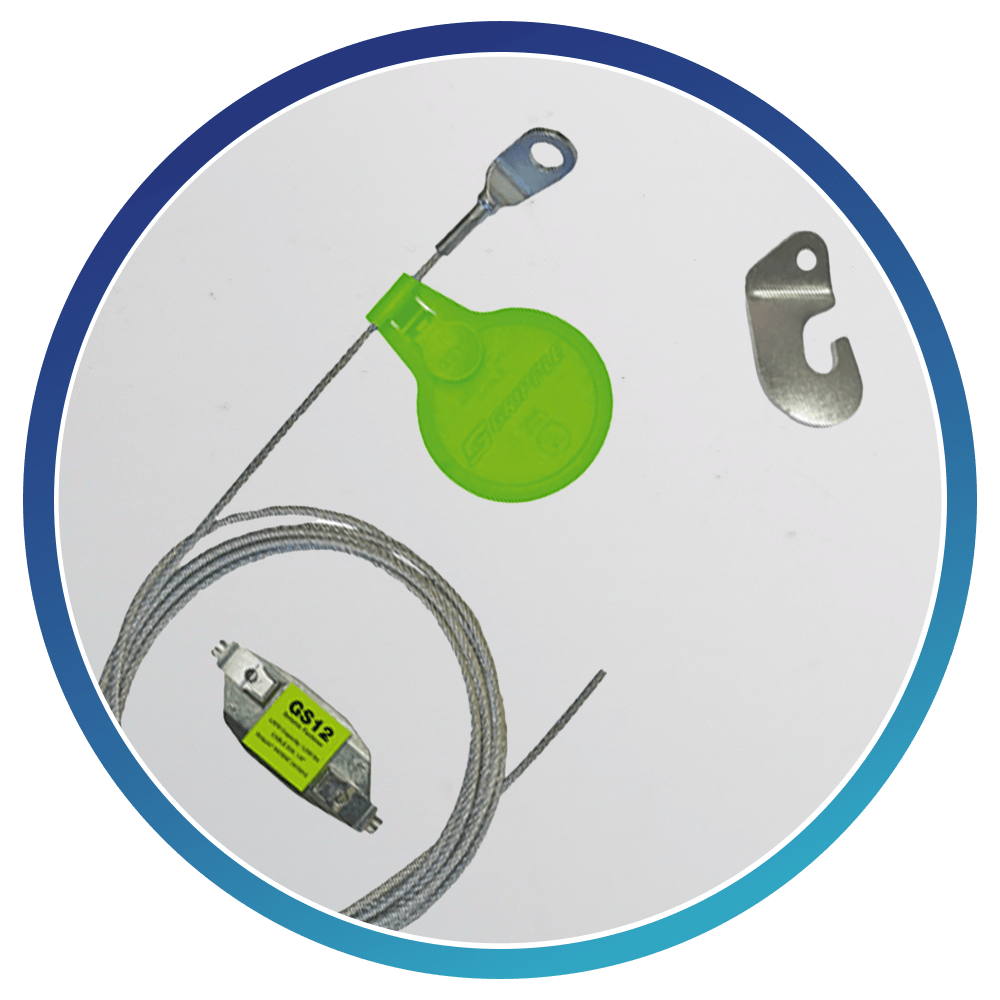

Specifically designed and engineered to brace and secure suspended nonstructural equipment VAV boxes fans unit heaters small in-line pumps etc and components HVAC duct conduit cable tray and piping within a building or structure

Gripple

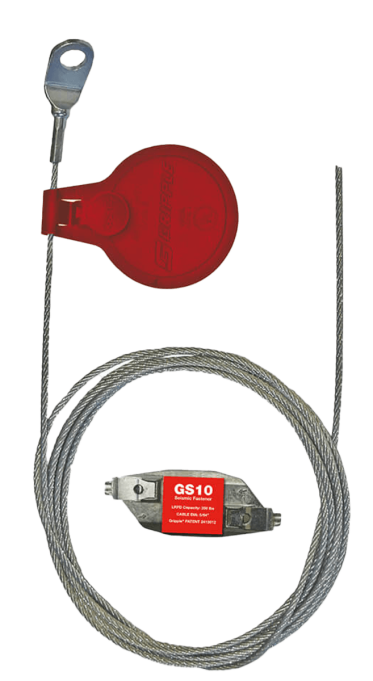

Lockable Plus

Combining push-fit technology with a one-step lock to create a fast and secure method to anchor or brace structures, the Lockable Plus is a simple way to quickly secure a catenary span and is easily installed in under one minute.

Gripple New Zealand

Seismic Bracing & Engineering Services

Gripple's Range of Applications

The Gripple New Zealand product range is perfectly suited for a range of bracing and suspension applications. Industry proven around the world, Gripple has been used as a fast and effective solution on thousands of installations around the world.

Gripple’s engineered seismic bracing systems are designed and tested in accordance with NZS4219 to brace and secure suspended non-structural equipment.

Select an application for more information on how Gripple products can be utilised in your industry.

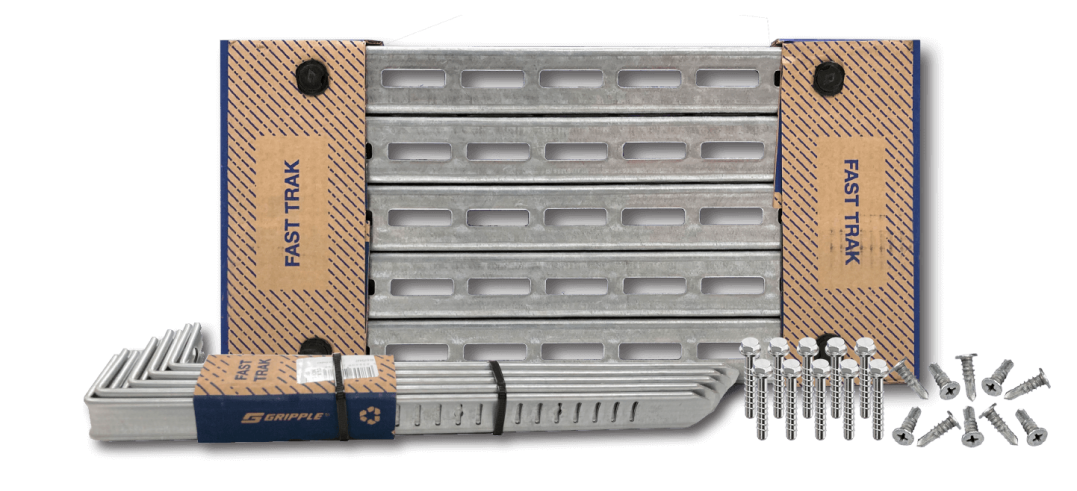

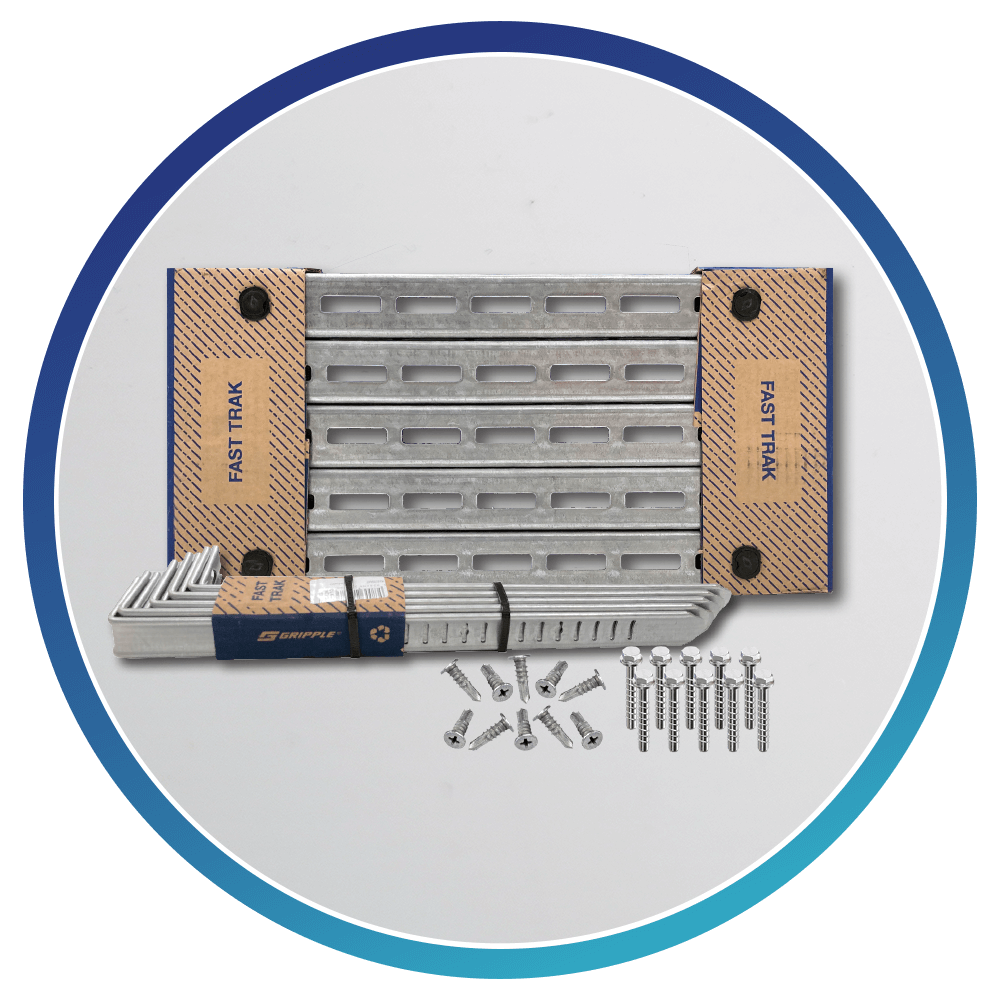

Product Range

Gripple New Zealand's innovative products are designed to be easy to transport and provide a sleek, aesthetic finish, Select a product range for more information on how Gripple can benefit you. Save up to 85% installation time too!

Your time is valuable, make the change to Gripple

Time & Material Savings

Seismic Testing

Health & Safety

High Quality Finish

News & Projects

20Jan 26

Flexible Signage Suspension for Retail Spaces

Creating clear, adaptable signage in a retail environment that requires a suspension solution that is…

01Dec 25

Christmas Closure

Office & Warehouse Holiday Hours We close at 2pm Friday 19 December, last dispatch at…

03Nov 25

Gripple & Rikta attended All Energy 2025

A huge thank you to everyone who visited the Gripple ANZ stand at Melbourne Convention…